The most common way to treat water hardness is to remove the minerals causing it, and an ion-exchange water softener is the easiest way to treat the problem. When a water softener removes calcium and magnesium, it remedies the symptoms of hard water. These systems are Whole House systems, they treat all of the water entering the home.

Treatment for Hard Water-Softening

How Water softeners Work

Water softeners are whole house systems that work through a process called ion exchange which eliminates calcium and magnesium from the water. When the hard water enters into the mineral tank, it flows through a bed of spherical resin beads. These plastic beads, usually made from polystyrene, are charged with a sodium ion. The resin beads are anions, meaning they have a negative charge. The calcium and magnesium minerals have a positive charge, making them cations.

Since opposite charges attract, the negative charge of the minerals is attracted to the positive charge of the resin beads. As the hard water passes through the resin, the beads grab ahold of the mineral ions and remove them from the water. When the bead seizes the mineral ion, the sodium ion is released. The column of resin strips all the hardness out of the water as it passes through the mineral tank, and softened water flows out into your home.

What are the components of a water softener?

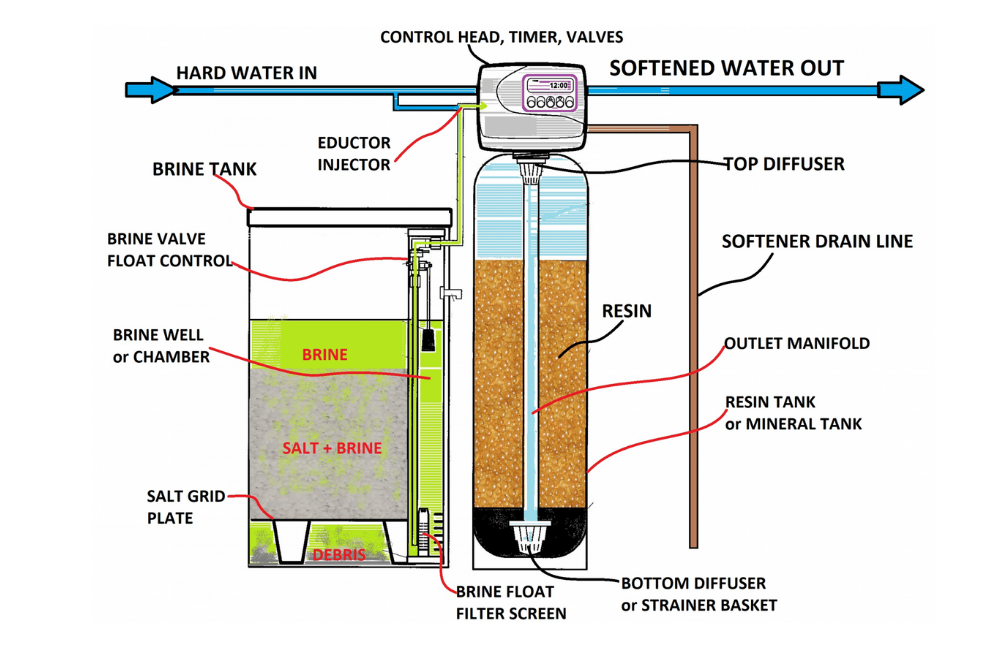

A water softener is made up of three components: a control valve, a mineral tank, and a brine tank. These three work in conjunction to remove the minerals from hard water, monitor the flow of water, and periodically clean the system through a regeneration process.

1. The mineral tank

The mineral tank is the chamber where the hard water is softened. The water supply line feeds the hard water into the tank. The water seeps through the bed of resin beads, depositing the water-hardening calcium and magnesium ions. The water exits the tank soft and flows through your pipes and out to your household appliances.

2. The control valve

The control valve measures the amount of water passing through the mineral tank and into your house. The valve houses a meter that tracks the volume of water entering the mineral tank. As hard water flows through the mineral tank, the resin beads exchange their sodium ions for hardness ions. Over time, this depletes the capacity of the resin to continue to effectively soften water. Before the beads become too burdened with mineral content to continue removing calcium and magnesium ions, the control valve automatically initiates a regeneration cycle. This maximum capacity is pre-programmed into the control valve’s onboard computer and is based on a range of factors, like the size of your house, the number of occupants, and the hardness of your water. Control valves are demand-initiated controllers, which allow water softening units to be extremely efficient.

3. The brine tank

The brine tank aids the water softening system in regeneration. It is a shorter tank that sits adjacent to the mineral tank. The brine tank holds a highly concentrated solution of salt (or sometimes potassium) to restore the resin beads’ positive charge. Salt is manually added to the brine tank in the form of pellets or blocks. These dissolve in the water at the bottom of the tank. When the control valve registers the softening capacity of the resin is diminishing, the heavy brine solution is drawn out of the tank and flushed through the resin in the mineral tank. If the brine tank runs out of salt, the water passing through the unit will no longer be softened.

How does water softener regeneration work?

Regeneration cycles inundate the resin beads with a highly concentrated brine solution, washing off the hardness minerals and draining them out of the system. The resin beads are recharged and primed to again eliminate the hardness minerals. Resin beads are extremely durable and can effectively soften your water for 15 years or longer. Water softeners regenerate by one of two methods: co-current or counter-current regeneration (also referred to as downflow brining and upflow brining.)

Co-current regeneration cycle

In a co-current regeneration cycle, the brine solution enters the mineral tank in the same direction as the service flow. The brine solution flows down the depth of the bed of resin beads and an ion exchange process occurs again, only this time in reverse. As the brine flows over the beads, the salts force the beads to release the magnesium and calcium ions in exchange for the sodium ion.

As the brine passes through the resin, an increasingly-concentrated surge of hardness minerals forms and flows through the entirety of the system. As the brine solution pushes more hardness minerals through the bed, continuous exchange and re-exchange of minerals and regeneration ions transpires. By the time the water has exited the tank, the solution’s strength is significantly reduced. In a co-current regeneration cycle, the highest charged beads will be on the ones at the top of the tank. Co-current regeneration uses more water and salt to complete the regeneration process than counter-current.

Counter-current regeneration cycle

In a counter-current regeneration cycle, water enters the tank through the bottom of the mineral tank, where the water usually exits. The countercurrent cycle runs the brine up the resin bed, beginning at the bottom where the resin beads are usually the least depleted. This means there are fewer hardness minerals initiating re-exchange during the regeneration cycle. The brine is less depleted by the time it reaches the top of the resin bed, where the softener first makes contact with the hard water. A counter-current cycling water softener uses 75% less salt and 65% less water than co-current cycling.

It also distributes the recharging sodium ions more equitably. In a countercurrent cycle, the most highly charged beads will be at the bottom of the tank, right before the water exits into the house. These are also known as high efficiency water softeners and are the only type that True Water Quality installs.

DOWNLOAD BROCHURE – ENTIPUR SOFTENER SYSTEM